How to Design and Construct Palisade and Panel Fence Corners

When you’re installing a fence that has round posts, like chain link fence, diamond mesh fence, and many kinds of rolled welded mesh fence, corners aren’t much of a problem. You simply install a post and then run your fence in whatever direction it needs to go.

However, when you’re installing higher security, more rigid types of fences like palisade fences or even some kinds of panel fences, corners can be a lot trickier. Let’s look at a few palisade and panel fence corner design options that might work for your fence.

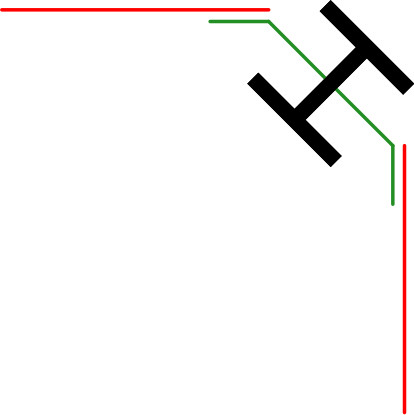

45 Degree Installation and Custom Fittings

If you’re installing a palisade fence, you’ll probably be using IPE posts or I-beam posts. If you are, then one way to construct 90-degree corners is to install the fence post at a 45-degree angle and then use a custom fitting (in the case of the picture, a corner fishplate which is green in our sketch.)

As you can see in the image, this allows the fence (which is red in the image) to be installed to create a 90-degree corner.

A similar effect can be achieved using square posts for ornamental fences if you have a swivel bracket or another custom fitting that can be angled appropriately.

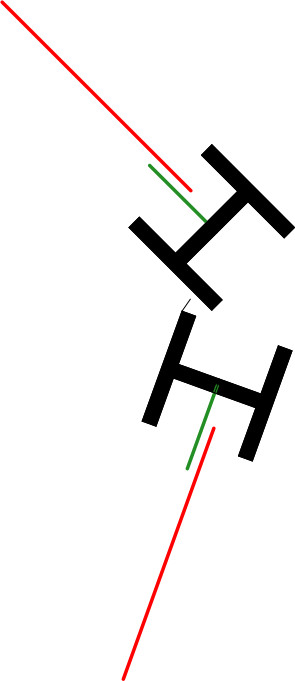

Double Corner Posts

Sometimes, the angle that your adjacent fences need to be installed at just won’t work, even with angled posts and custom fittings.

Sometimes, the angle that your adjacent fences need to be installed at just won’t work, even with angled posts and custom fittings.

In cases like these, a good solution is to install two fence posts in one concrete footing at that corner. This allows you to install the adjacent fences at any angle you need them to be at without having to spend more for extra excavations and concrete. There’s also no need to figure out how to close a gap between two fence posts installed in their own footings because posts can be installed very close together.

In this sketch, you can see the fence posts in black and the fishplates or brackets in green. Each fence is indicated in red, and these could be installed at any angle to the corner in question simply by changing the angle of the posts.

Cutting and Welding On Site

Some fence companies might suggest cutting and welding panels, posts and fittings on site, and while this is a possible solution for complex fence corners, it does create its own set of challenges.

One is that the quality and appearance of these kinds of welds can vary a lot, and this might become a weak point in your high-security fence system.

Another is that cutting and welding usually involve removing galvanizing and any other coatings on the fence. This will require careful touch-ups to prevent rusting, and it could also affect the material warranty on the fence. Some fence manufacturers who have corrosion warranties will not honor them if the fence has been tampered with in this way.

Designing and Estimating Panel Fences

Challenges like the ones mentioned here, dealing with irregular angles, changes in elevation and other site-specific features, all affect the price of panel fence systems.

It’s very important, if you have a palisade fence or panel fence system fence project, that you have the fence companies providing the quotes visit the site so that they can see these features themselves.

A good set of drawings will provide some useful information for designing and estimating panel fences, but actually seeing the site and the fence line will ensure that everyone has the information they need to design solutions that will work.

Always look for fence companies who have a lot of experience installing palisade or panel-type fence systems for projects like these. This is almost certainly a job for a specialist commercial or high-security fence company.