How to Cut a Metal Fence Panel

Metal panel fences like bar fences, ornamental fences, and palisade fences look great, but they are often a little trickier to install than other types of fences.

One reason for this is that they have a fixed width, and most fence lines don’t conveniently require exact full panels, so you will probably need to make a few cuts to make your fence panels fit properly. Let’s take a closer look at how to cut a metal fence panel correctly.

Tools Required to Cut Metal Fence Panels

Before we get into the details of how to cut a metal fence panel correctly, it’s important that you get the right tools, equipment, and supplies together for cutting metal fence panels. Here’s what you might need:

A Cut Off Saw or Chop SawOften, the easiest way to cut metal fence panels is to use a cut-off saw or chop saw that has a base and a lever that you can pull down to cut your fence material. Some cut-off saws or chop saws are used “free hand” with a handle, but this gives less control and makes it harder to get a square, even cut. It’s also a little more dangerous because you have less control over the saw and the material being cut. |

||

Angle GrinderIf you don’t have a cut-off saw or chop saw, and you don’t want to buy or rent one, an angle grinder is a good second choice to cut metal fence panels. Again, however, pay close attention to safety! You want to make sure your fence panels are firmly clamped in place and can’t move when you start cutting, and you always need to use the guard on the blade and wear appropriate eye protection and gloves. |

||

A DrillAnother tool you will need when you are cutting metal fence panels is a drill. Most metal fence panels have pre-drilled or pre-punched holes in the top and bottom rails of the panel to allow you to fix them to the posts. However, once you cut part of the panel away, you will need to redrill holes so you can bolt or attach them in place. Make sure you also have the right drill bits – HSS bits are usually best for metal fence panels. |

||

A Good Measuring TapeWhen it comes to cutting metal fence panels, you want to follow the old carpenter's wisdom that says you should always “measure twice and cut once.” A good measuring tape is crucial to make sure you are cutting in the exact right place. Make sure you measure carefully between your installed posts and that you measure the panel correctly, and always double-check everything before you start cutting. Metal fence panels aren’t cheap, and the last thing you want to do is wreck one by cutting in the wrong place. |

||

China MarkersThis might seem a little odd as an addition to our list of tools and equipment for cutting metal fence panels, but it’s often tricky to figure out how to mark them for cutting without leaving visible marks on the fence. One of the best things we’ve found for the job is china markers, which are a waxy kind of crayon that you can mark the surface of your fence panel with, but you can wipe it off fairly easily too. |

||

Cold Galv and Touch-Up PaintThe last thing you need to have in your metal fence panel cutting toolbox is cold galvanizing and touch-up paint. When you cut the ends of a metal fence panel, you will create exposed areas that are not protected from corrosion by the coatings on the rest of the panel. Cold galvanizing and touch-up paint will help to protect those cut edges and ensure your panels don’t start rusting prematurely. Just make sure you follow the package instructions properly to get the right amount of coverage and to ensure you let the paint dry enough to stick properly. |

||

When to Cut Metal Fence Panels

The next thing we need to talk about is when you need to cut metal fence panels.

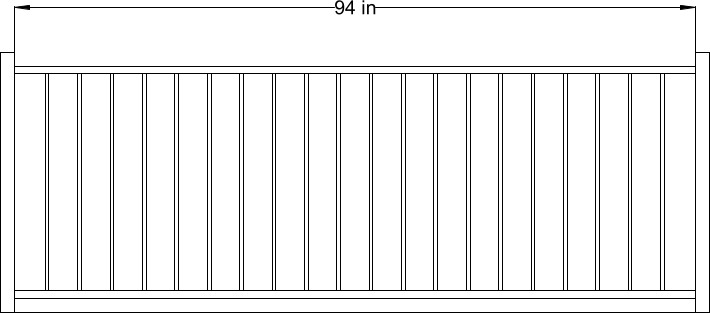

As you can see in the image below, metal fence panels come in defined panel sizes. In this case, the space between the two fence posts is 94 inches. This will vary based on the type of metal fence panel and the fence specification, but there’s always a standard panel size you will be working with.

Unfortunately, fence lines don’t care what your panel size is, and most fence lines will have at least a couple of cut panels – usually at each end of the fence line, but sometimes in other places to accommodate features along the fence line.

When you have a space between fence posts that will not fit your standard panel size, you will need to cut your metal fence panel.

Metal Fence Panel Cutting Basics

No matter what kind of metal fence panels you are cutting, there are a few general rules you need to follow:

- Measure both the top and bottom rail position on your fence posts – just because they look the same distance apart to the naked doesn’t mean they are, and if they’re not square, you will need to compensate in your cuts

- If you have short fence lines, it’s better to have a cut panel at both ends of the fence line than one short panel on the end of one side – this helps to make your fence lines look more even and balanced

- Don’t forget that you can reuse the offcuts of panels from one fence line on another, so plan your cuts carefully – if there’s an area where you can reuse an offcut, you will save money on the fence

- Cut slowly and smoothly – don’t rush your cuts – it could result in rough edges that you will need to attend to later

The Wrong Way to Cut Metal Fence Panels

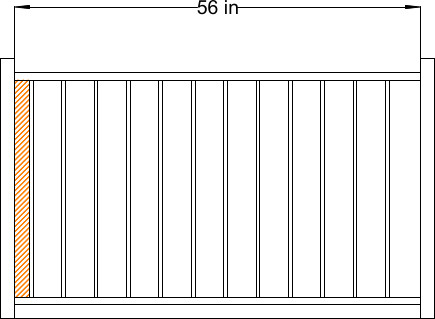

We’ll get to the right way to cut metal fence panels in a moment, but first, take a look at an example of the wrong way to cut metal fence panels.

When you’re building any fence, the goal is always to have everything look as even and balanced as possible, and in this example, we’ve cut 38 inches off only one side of the panel. This results in one very small space on one side of the panel and a normal space on the other. This doesn’t look balanced or even, and it’s not the correct way to cut metal fence panels.

The Right Way to Cut Metal Fence Panels

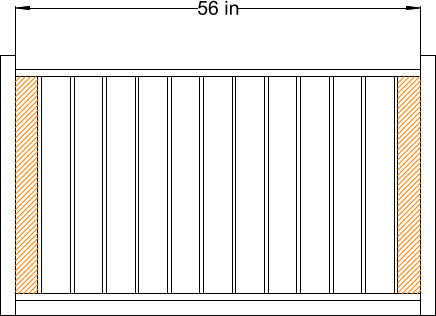

Now, look at the image on the right. This illustrates the correct way to cut metal fence panels.

As you can see, in this example, the same 38 inches have been cut off the panel, but this time, the cut sections at each end of the panel are the same width, which looks more even and balanced.

A More Complicated Fencing System

As you can see from this article, there’s a little more thinking and planning that goes into installing a panel fence system, and if you aren’t skilled at installing fences, it is easier to make mistakes with this kind of fence system.

If you’re not sure that you can handle the planning and installation of a metal panel fence, it’s usually best to look for a fence professional in your area who has this kind of experience. You will pay more for installation, but you may well save on materials and even tools since you won’t be wasting fence material and you won’t need to buy or rent any equipment.